Do you know how ethanol is made? Commercial production of fuel ethanol in the United States involves breaking down the starch present in corn into simple sugars (glucose), feeding these sugars to yeast (fermentation), and then recovering the main product (ethanol) and byproducts (animal feed and carbon dioxide). Ethanol is an alcohol produced through the process of yeast fermentation of sugars.

The Corn fermentation in a bag lesson gives students the opportunity to design and set up a fermentation lab.

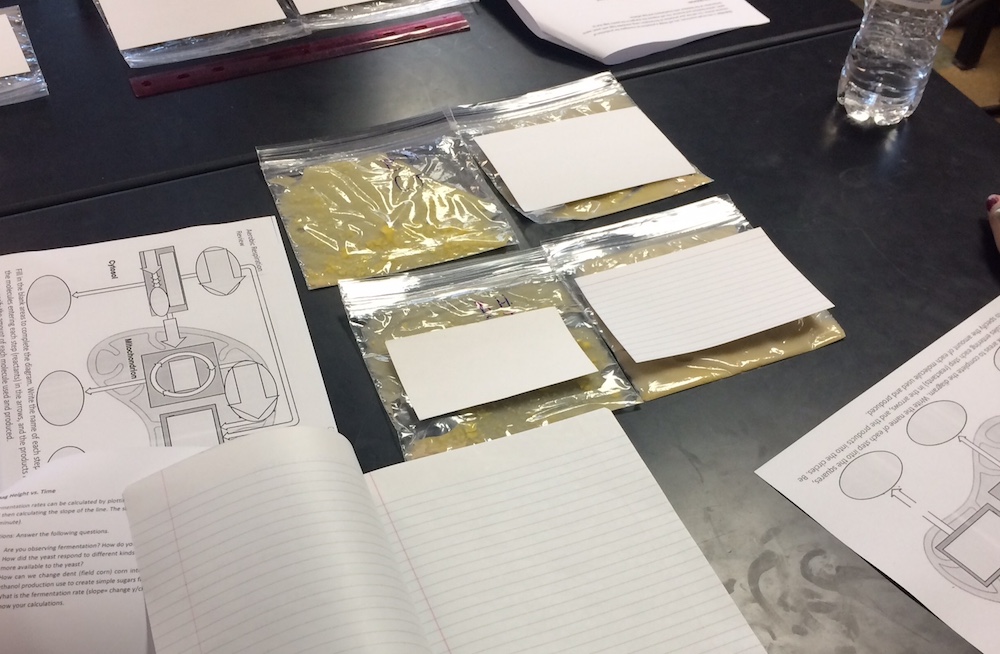

Ann Rougier teaches at Stivers School for the Arts. She attended the Feed the World summer workshop and used this lesson with the content topic of Cell Respiration, anaerobically. The students were given four types of corn products, two different enzymes. They designed a procedure to investigate the production of industrial ethanol and tested their procedure of fermentation using resealable bags with yeast, warm water, various feedstock and enzymes. Finally, they measured the changes in the plastic bags due to fermentation of the feedstock using breathalyzers and checking bag inflation.

Rougier said, “They designed the experiment based on the available materials. This gave the students an opportunity to see how to set up a good experiment and how too many variables can influence and ultimately deliver bad data.”

Lab partners had a day to design and set up (creating data tables, dry materials, etc.) and a day to complete.